|

CAD/CAM Mold Design

|

|

| We've been using 3-D CAD/CAM in our design work since 1992 |

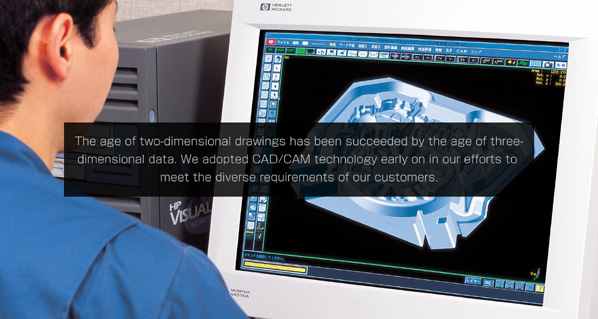

| In 1992 we participated in a project in

Japan for an American manufacturer. It involved the production of molds for aircraft parts. It was at that point that we introduced CAD/CAM into our operations. Most of our work until that time had employed two-dimensional drawings, but for the new project we set up a state-of-the-art design environment in order to be able to meet every conceivable customer requirement. In addition to investing in the latest equipment, we place heavy emphasis on the training of design personnel and on attentive customer service. To help ensure that the finished molds are of the highest quality, we present our clients with carefully worked out proposals from the initial discussion stage onward. This is just one example of the high level of service we provide. |

|

| Meeting the

demands of international competition and providing quick transfer of 3-D data |

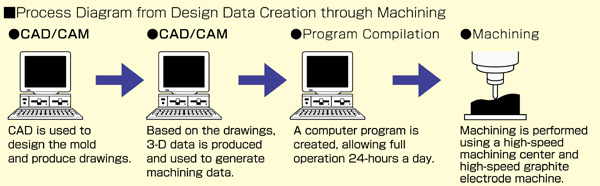

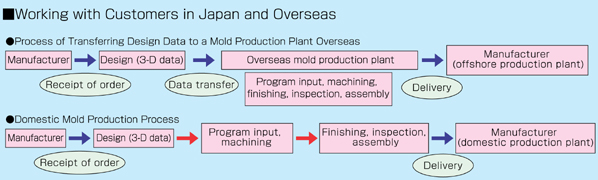

| Our industry today is marked by fierce competition on

a global scale. In order to survive in this business climate, a company must provide superior products and service backed by advanced technology. Only in this way is it possible to provide support customized to every detail of the customerfs requirements. In response to the current trend, we have developed a system that enables us to send 3-D machining data created using CAD/CAM directly to our clientsf production plants overseas. This service is an adjunct to our existing mold fabrication business. Our traditional commitment to quick response and superior quality remains the same, whether our clients are located in Japan or overseas. |

|

| NC data we have prepared is sent overseas and used to

manufacture molds at an offshore plant (in China, Taiwan, the Philippines, Indonesia, the Americas, Europe, or the like) in another country. It is then used for mass production at the manufacturerfs facility, either in that country or in yet another. |

| Copyright 2004 MORIKAWA KANAGATA Co., Ltd. All Rights Reserved. |