High-Speed Machining

|

High-Speed Machining

|

|

| Always looking ahead by utilizing

the latest and most reliable equipment |

|

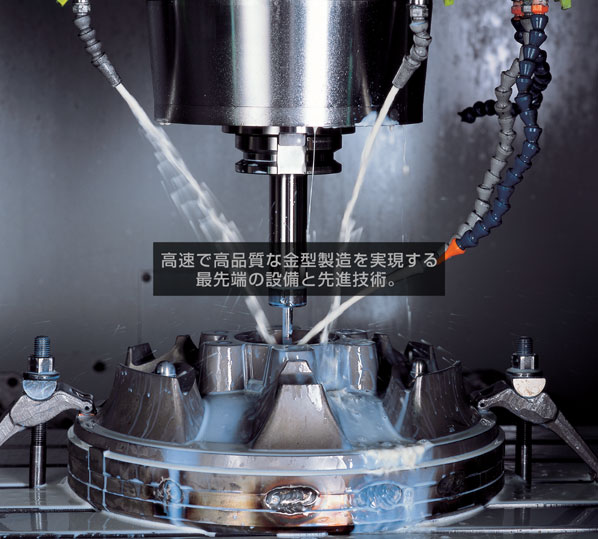

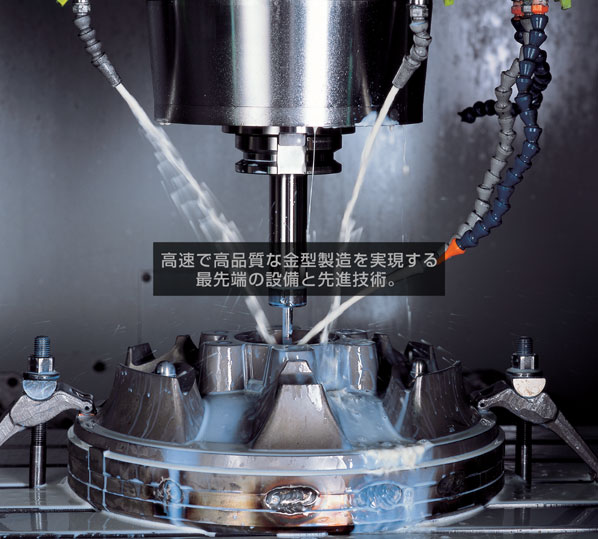

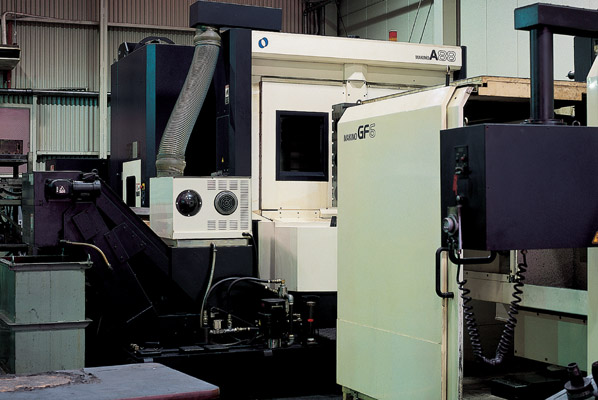

| Our state-of-the-art high-speed machining centers perform

mold machining quickly and with a high level of precision. Most molds can be machined directly and require no supplemental polishing. These machining centers are the main element in our mold-making equipment lineup, and they allow us to meet a variety of requirements. Their superior technology and performance enable us to shorten delivery times, reduce costs, and improve productivity. At the same time, the rapid pace of improvements in machining technology and software automation means that new models are being developed one after another. As machine tools become more diverse and their service lives shorter, constantly acquiring new systems and keeping up to date becomes a challenging and complex process. To keep ahead we monitor the latest information on developments and put a strong emphasis on obtaining new and improved models as they become available. Our machine tools are manufactured by Makino, a world leader in the field. They provide excellent reliability and enable us to produce molds of the highest quality. The superior molds we fabricate for our clients are the result of the best technology and unmatched expertise. |

|

| State-of-the-art

machine tools providing the highest levels of performance |

| Our choice of Makino machine tools is based on their innovative

technology. Makino's Super Geometric Intelligence* (Super GI) control system makes possible high-speed machining with greater precision than conventional machine tools are capable of achieving. Superb precision is maintained even at cut-advance speeds 10 to 100 times faster than was previously possible. In addition, detailed NC data enables machining of curved surfaces using three, four, or even five axes simultaneously. Flush Fine* (FF) milling, a high-speed machining process designed for hard materials, produces results that are only obtainable using electric discharge machining. It makes it possible to machine difficult-to-mill alloys or materials up to HRC67 in hardness by maintaining both tool and work at a constant temperature, ensuring a constant cutting load, and preventing swarf abrasion. The FF process is also much faster than conventional methods, making it possible to complete a job that would have previously taken one week in just two hours. The combination of Makinofs superior machine tool technology and our own expert technicians enables Morikawa Kanagata to produce molds perfectly suited to our clientsfrequirements. * Product data provided by Makino Milling Machine Co., Ltd. |