Quality Assurance

Once the machining

stages are finished,

the completed mold undergoes quality

checking, finishing, dimensional

inspection, and assembly, before being

shipped to the manufacturer who

ordered it.

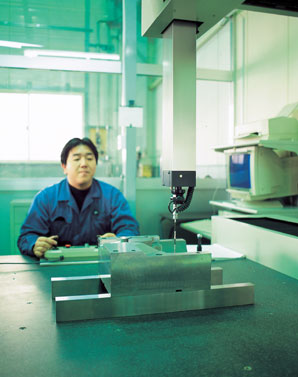

completed, the mold undergoes quality

checking, hand polishing, and careful

finishing. Then data analysis is undertaken as

part of the rigorous dimensional inspection

stage, including error analysis and spatial

accuracy correction performed using three-

dimensional measuring equipment. Only after

the finished mold parts have passed these

tests are they assembled and shipped to the

client. Morikawa Kanagata meets the

requirements of customers by means of an

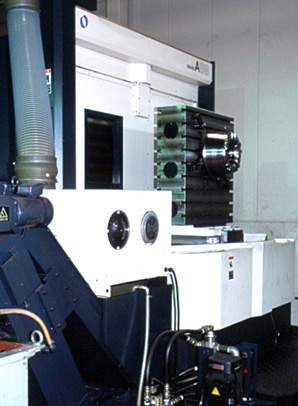

integrated manufacturing system

incorporating design, programming, milling,

electric discharge machining, and

inspection, coupled with a demanding quality

control regimen.