Electrical Discharge

Machining

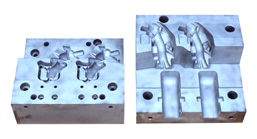

materials for which high-speed machining centers optimized for high- precision milling are

not suitable. Work that cannot be milled using a machining center includes materials that are even harder than the cutting tool, difficult-to- mill materials, and narrow or deep cavities. For

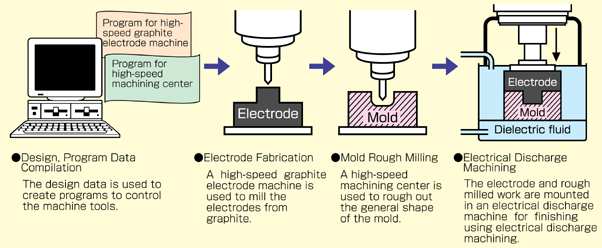

these, electrical discharge machining is the solution. First, a high-speed graphite electrode

machine is used to fabricate the male electrodes from graphite, which is easy to mill. These

are then used in an electrical discharge machine to make the molds and female dies.

For example, it is not possible to mill an object with deep, narrow grooves using a machining

center, but it is possible to mill a male die that is the inverted configuration of the object.

Once one has a male electrode, an electrical discharge machine can be used to mill the desired

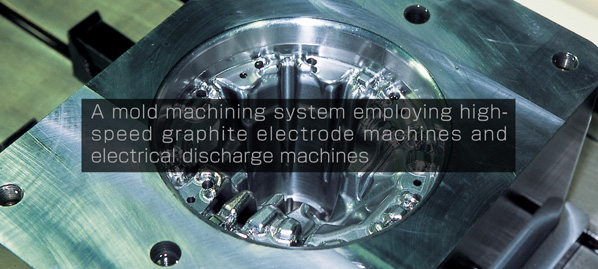

mold. In this way, a high- speed graphite electrode machine and an electrical discharge

machine can be used in tandem to fabricate molds with difficult-to-mill configurations. In

addition, the use of high-precision automated machine tools makes continuous unattended

operation possible. This contributes to shorter delivery times and reduced cost.

For products where the cosmetic design is an important consideration, and where there is a

need to check the final form against a design model, a prototype can be fabricated in graphite.

This makes it possible to confirm the final form of the product and to produce a mold that

matches the design model precisely. Once the final confirmation is complete, an electrical

discharge machine is employed to fabricate the mold, using an electrode made of graphite.